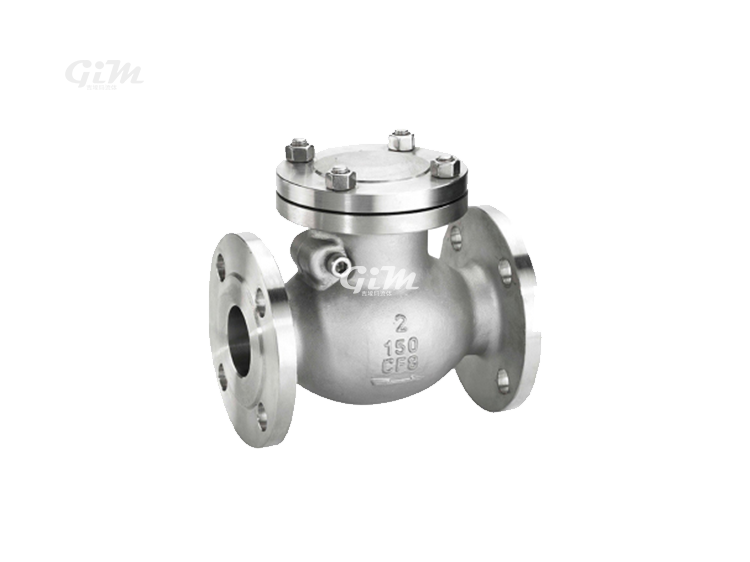

Stainless Steel Swing Check Valve

- Support Customization

- Two-Year Warranty

- Global Shipping

- Multiple Payment Methods

Overview:

The Stainless Steel Swing Check Valve is designed to prevent backflow in piping systems by allowing flow in one direction and automatically closing when flow reverses. Its stainless steel construction provides durability and resistance to corrosion, making it suitable for various demanding applications.

Product Features:

- Design and Construction:

- Swing Mechanism: Features a swing-type disc that pivots on a hinge or pin. The disc swings open to allow flow in the forward direction and swings closed to block backflow.

- Material: Constructed from high-quality stainless steel (e.g., 304, 316), offering excellent resistance to corrosion and high temperatures.

- Flow Direction:

- Allows unrestricted flow in one direction and closes automatically when flow direction reverses.

- Prevents backflow, protecting the system from potential damage and ensuring smooth operation.

- Pressure and Temperature Ratings:

- Pressure Rating: Designed to handle various pressure ranges, typically from 150 psi to 1500 psi or higher, depending on the valve size and design.

- Temperature Rating: Suitable for high-temperature applications, often ranging from -50°C to 450°C (depending on the specific stainless steel grade and design).

- Installation:

- Flanged Connections: Commonly available with flanged connections for ease of installation and compatibility with existing piping systems.

- Orientation: Can be installed in both horizontal and vertical positions, based on the system’s requirements.

- Sealing:

- Seat Material: Typically features a soft seat or metal seat, designed to ensure a tight seal when the valve disc closes, preventing leakage.

- Gaskets and Seals: Made from materials that provide effective sealing while withstanding high temperatures and pressures.

- Maintenance:

- Easy Maintenance: The simple design of the swing check valve allows for straightforward maintenance and inspection.

- Repair and Replacement: Components such as the disc and seat can be replaced or repaired as needed to ensure continued reliable operation.

- Applications:

- Water Treatment: Used to prevent backflow in water supply and treatment systems, ensuring the integrity of the water supply.

- Oil and Gas: Protects pipelines and equipment from reverse flow, maintaining efficient and safe operation in oil and gas systems.

- Chemical Processing: Suitable for handling chemicals and preventing contamination by ensuring unidirectional flow.

- Power Generation: Used in power plants to manage steam and other fluids, ensuring proper flow and system protection.

- Industrial Processes: Ideal for various industrial applications where reliable backflow prevention is critical.

Advantages:

- Corrosion Resistance: Stainless steel construction ensures durability and resistance to corrosion, making it suitable for harsh environments.

- Reliable Performance: The swing mechanism provides effective backflow prevention and reliable operation.

- Versatile Applications: Suitable for a wide range of applications, including high-pressure and high-temperature environments.

- Ease of Installation: Flanged connections and versatile installation options simplify integration into existing systems.

- Low Maintenance: The simple design allows for easy maintenance and repair, reducing downtime and operational costs.

Conclusion:

The Stainless Steel Swing Check Valve is a robust and reliable choice for preventing backflow in various industrial applications. Its stainless steel construction offers superior corrosion resistance and durability, making it suitable for challenging environments. With its effective swing mechanism, versatile applications, and ease of maintenance, this valve is a valuable component in maintaining the integrity and efficiency of piping systems.